Optional accessories

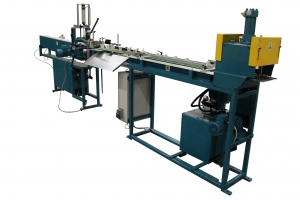

CAC

Automatic core loader centrifugal system

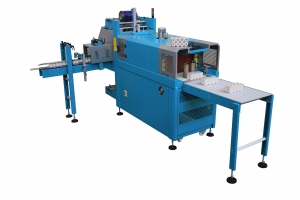

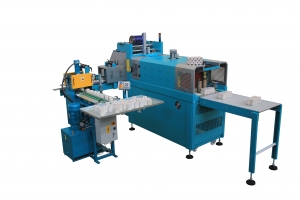

PR

Press machine for rolls with manual

feeding and rotary table at exit

AM 60

Automatic shrink wrapping machine

for cash register rolls

PR-AM

Press machine for rolls with manual feeding and automatic shrink wrapping

RB-PR

Linea automatica separatrice e

pressatura dei rotolini

Slitting rewinding machine to produce cash register rolls, multiplies rolls, fax rolls, charts rolls, lottery tickets rolls.

Features

WORKING WIDTH mm: 550/1100 (multiplies) – 1350/1600 (one ply)

UNWIND DIAMETER mm: 1000 (multiplies) – 1250 (one ply)

REWIND DIAMETER mm: 320

SPEED: 350 mt/min

Productivity in 8 hrs including time of changing mother rolls:

900 CYCLES FOR 20 MT LONG ROLLS

720 CYCLES FOR 50 MT LONG ROLLS

580 CYCLES FOR 80 MT LONG ROLLS

This automatic machine is recommended for small, medium and big production capacity as the setting for different width and diameter is very easy and fast. The automatic sequence to descend top rider pressor roll, tuck-in of the paper over the cores,start up motor, warning stripes mark activation, deceleration and final stop does not require operator attention that during this part of the cycle can discharge the finished rolls and prepare the new rewinding shaft with cores for next cycle.

The automatic tucker givrs you 20% more in production than machine with manual tucker.

The winding system is by surface drums and the tension control is very accurate controlled by a pneumatic disk brake. The machine is equipped by inverter motor, electronic metre counter to set length of warning stripes slow-down speed final stop, circular slitting knives with spacers multisizes.

The machine can be provided with extra unwind stations to produce 2 and 3 copy rolls, flexographic station for printing in line up to 2 colours with registration, accumulator for non-stop printing and accessories machines to speed up production as automatic core loader, roll breaker and flattening machines, shrink wrapping machine for packaging.